自動(dòng)化焊接設(shè)備的三大特點(diǎn)

來源:http://www.ckcdvd.com/ 發(fā)布時(shí)間:2023-05-18 瀏覽次數(shù):0

如今自動(dòng)化技術(shù)更加成熟,自動(dòng)化焊接設(shè)備隨之出現(xiàn),并實(shí)現(xiàn)了機(jī)械制造領(lǐng)域中的應(yīng)用。將自動(dòng)化焊接設(shè)備應(yīng)用于機(jī)械制造中,能夠更好地保障機(jī)械制造效率及質(zhì)量,提升焊接工藝精度,下面來講講山東自動(dòng)焊接設(shè)備的三大特點(diǎn)。

Nowadays, automation technology is becoming more mature, and automated welding equipment has emerged, achieving efficient applications in the field of mechanical manufacturing. Applying automated welding equipment to mechanical manufacturing can better ensure the efficiency and quality of mechanical manufacturing, improve welding process accuracy. Below, we will talk about the three main characteristics of Shandong automatic welding equipment.

1.科學(xué)智能化

1. Scientific intelligence

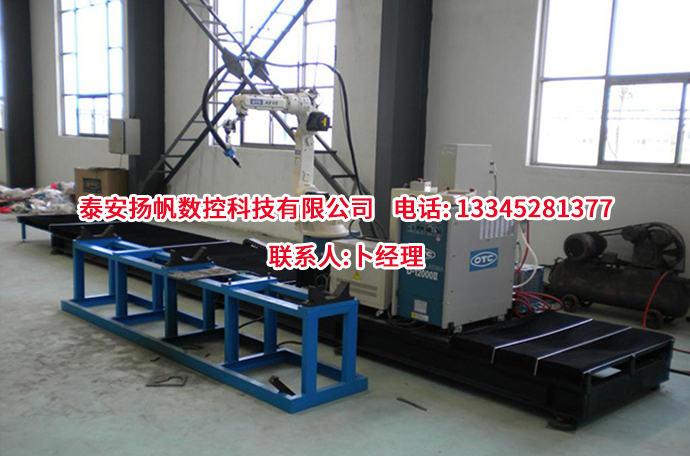

和傳統(tǒng)焊接設(shè)備及人工焊接技術(shù)相比較而言,自動(dòng)化焊接設(shè)備所具備的科學(xué)智能化特點(diǎn)是非常明顯的。自動(dòng)化焊接設(shè)備在機(jī)械制造中的應(yīng)用,實(shí)現(xiàn)了自動(dòng)化運(yùn)行。

Compared with traditional welding equipment and manual welding technology, the scientific and intelligent characteristics of automated welding equipment are very obvious. The application of automated welding equipment in mechanical manufacturing has achieved automated operation.

在智能化信息技術(shù)的支撐下,具備了人機(jī)交互的特征,賦予了其智能化操作的功能,能夠?qū)崿F(xiàn)對(duì)整個(gè)焊接工序、流程的數(shù)字化集中控制,尤其是對(duì)于較為精細(xì)的焊接部位,數(shù)字化集中控制能夠更好的保證焊接施工質(zhì)量。

With the support of intelligent information technology, it has the characteristics of human-computer interaction and is endowed with intelligent operation functions, which can achieve digital centralized control of the entire welding process and process, especially for more precise welding parts. Digital centralized control can better ensure the quality of welding construction.

在機(jī)械制造中,自動(dòng)化焊接設(shè)備的應(yīng)用和操作具備較強(qiáng)的程序性,對(duì)于自動(dòng)化傳感技術(shù)有著非常高的要求,進(jìn)而才能夠更好的滿足機(jī)械制造及焊接工作需求。

In mechanical manufacturing, the application and operation of automated welding equipment have strong programmability, and there are very high requirements for automated sensing technology, which can better meet the needs of mechanical manufacturing and welding work.

2.高精準(zhǔn)度與組合化

2. High precision and combination

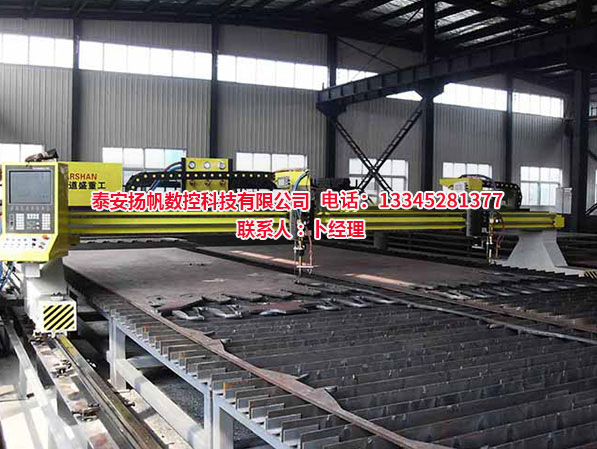

將自動(dòng)化焊接設(shè)備應(yīng)用于機(jī)械制造業(yè)中,具備了較高的精準(zhǔn)度及組合化特點(diǎn)。高精準(zhǔn)度主要體現(xiàn)在利用數(shù)控系統(tǒng)來實(shí)現(xiàn)對(duì)焊接精度的精準(zhǔn)化控制,確保焊接質(zhì)量達(dá)標(biāo)。

The application of automated welding equipment in the mechanical manufacturing industry has high accuracy and combination characteristics. High precision is mainly reflected in the use of CNC systems to achieve precise control of welding accuracy and ensure that welding quality meets the standards.

一般情況下,在應(yīng)用普通焊接設(shè)備時(shí)應(yīng)將其焊接精度控制在1mm內(nèi),禁止超過此標(biāo)準(zhǔn)。而應(yīng)用自動(dòng)化焊接設(shè)備,則能夠?qū)⒑附泳瓤刂圃?.5mm內(nèi),不難看出,自動(dòng)化焊接設(shè)備和普通焊接設(shè)備相比較而言,具備了更高的精準(zhǔn)度。

In general, when applying ordinary welding equipment, its welding accuracy should be controlled within 1mm and it is prohibited to exceed this standard. By using automated welding equipment, the welding accuracy can be controlled within 0.5mm. It is not difficult to see that compared to ordinary welding equipment, automated welding equipment has higher accuracy.

組合化特點(diǎn)主要體現(xiàn)在機(jī)械制造業(yè)在應(yīng)用自動(dòng)化焊接設(shè)備的過程中,往往將設(shè)備放在大型設(shè)備上,這些設(shè)備的應(yīng)用,不僅具備了綜合性特征,同時(shí)其運(yùn)行效率更高,能夠?yàn)闄C(jī)械制造及焊接工作提供巨大的便利。

The characteristics of combination are mainly reflected in the application of automated welding equipment in the mechanical manufacturing industry, which often focuses on large-scale equipment. The application of these equipment not only has comprehensive characteristics, but also has higher operational efficiency, which can provide huge convenience for mechanical manufacturing and welding work.

3.監(jiān)督與管理有機(jī)協(xié)調(diào)

3. Organic coordination of supervision and management

在機(jī)械制造中應(yīng)用自動(dòng)化焊接設(shè)備,使其具備了監(jiān)督和管理有機(jī)協(xié)調(diào)的特征。對(duì)于焊接設(shè)備的管理與控制,主要是利用網(wǎng)絡(luò)技術(shù)、計(jì)算機(jī)信息技術(shù)得以實(shí)現(xiàn)的。

The application of automated welding equipment in mechanical manufacturing has enabled it to have the characteristics of organic coordination between supervision and management. The management and control of welding equipment are mainly achieved through the use of network technology and computer information technology.

具體來說,自動(dòng)化焊接設(shè)備運(yùn)轉(zhuǎn)期間利用局域網(wǎng)有效管控銜接各項(xiàng)焊接流程,實(shí)現(xiàn)對(duì)焊接工作全過程的實(shí)時(shí)化監(jiān)督管理,及時(shí)的發(fā)現(xiàn)并遠(yuǎn)程判斷分析解決出現(xiàn)的故障問題,保證焊接作業(yè)的順利、開展。還有什么問題就來我們網(wǎng)站http://www.ckcdvd.com咨詢吧!

Specifically, during the operation of automated welding equipment, local area networks are used to effectively control and connect various welding processes, achieving real-time supervision and management of the entire welding process, timely detection, remote judgment, analysis, and resolution of fault problems, ensuring the smooth and safe operation of welding operations. If you have any further questions, please come to our website http://www.ckcdvd.com Consult!

上一篇:直縫專機(jī)可焊接什么以及注意事項(xiàng)

下一篇:數(shù)控焊接設(shè)備的工藝要點(diǎn)總結(jié)